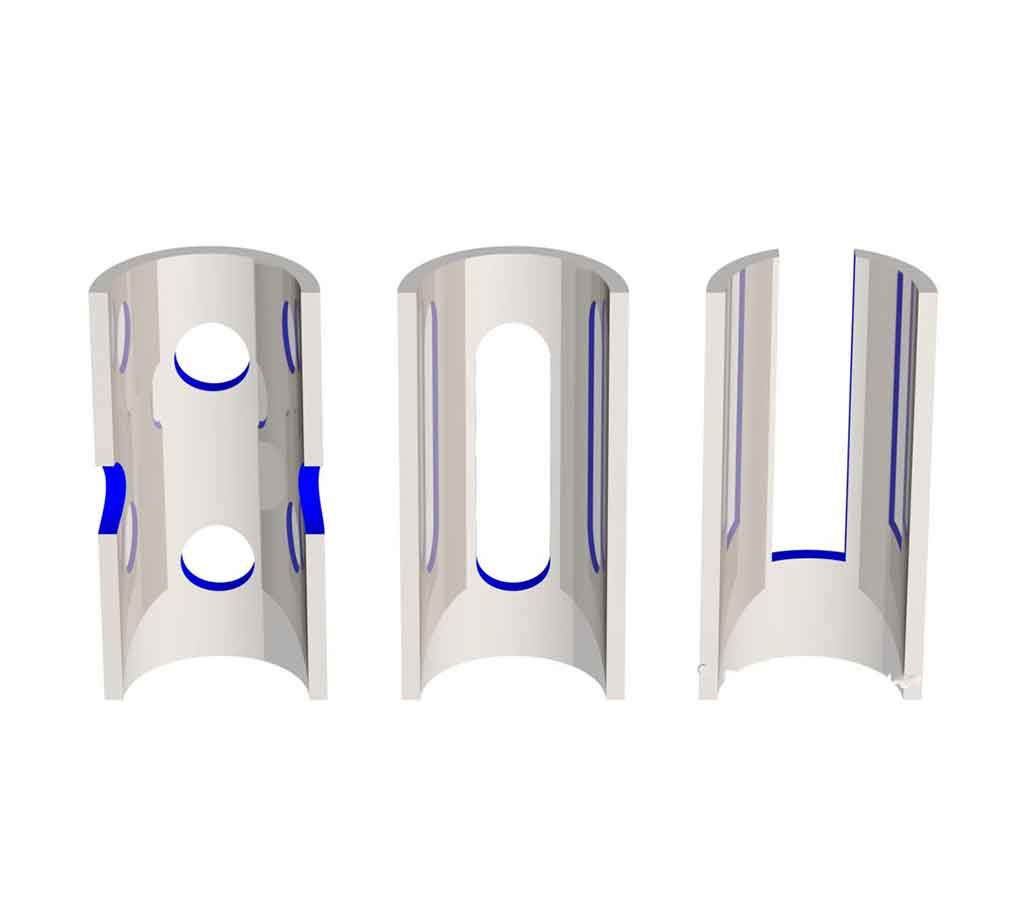

Our cumulative experience of more than 40 years has showed us that every company suffers with one common problem, Burrs. When you drill holes, you a lot of burrs. And then you deburr those holes with hand tools. We have developed patented plunge-type tools for finishing your holes, so that you can manufacture burr-free components without any off-line process starting at 1.45mm diameter.

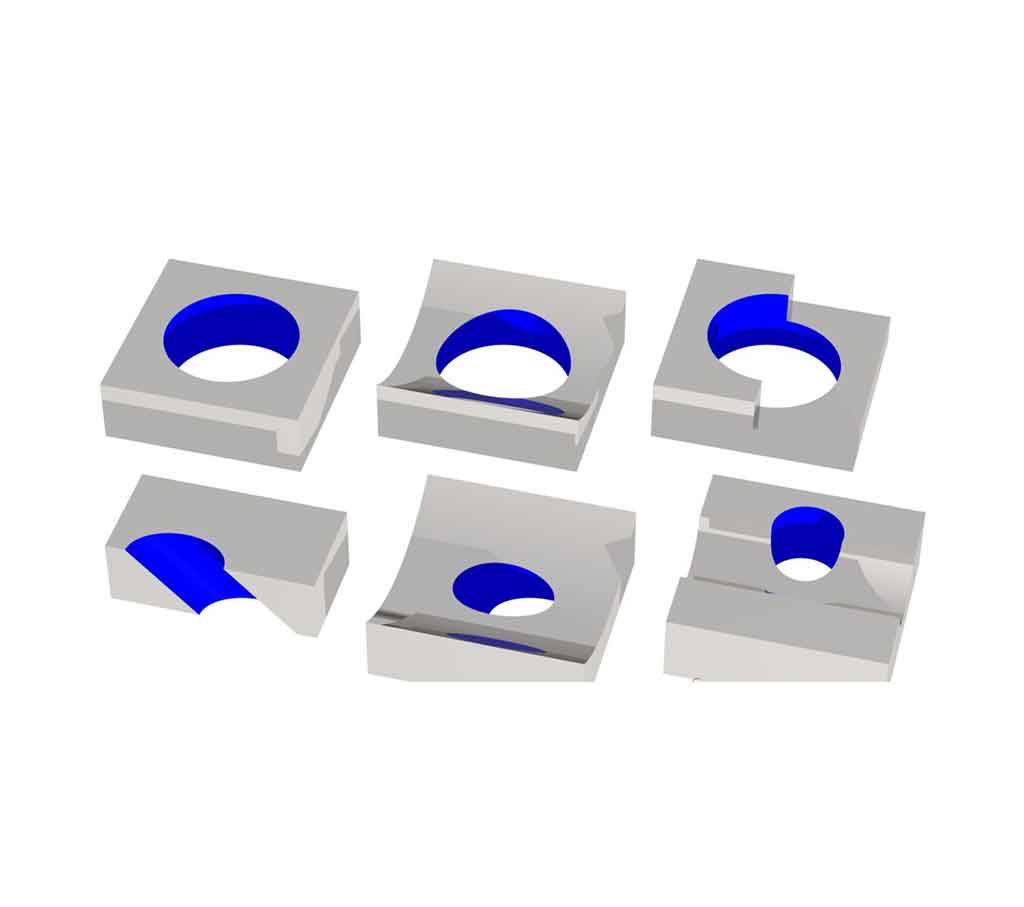

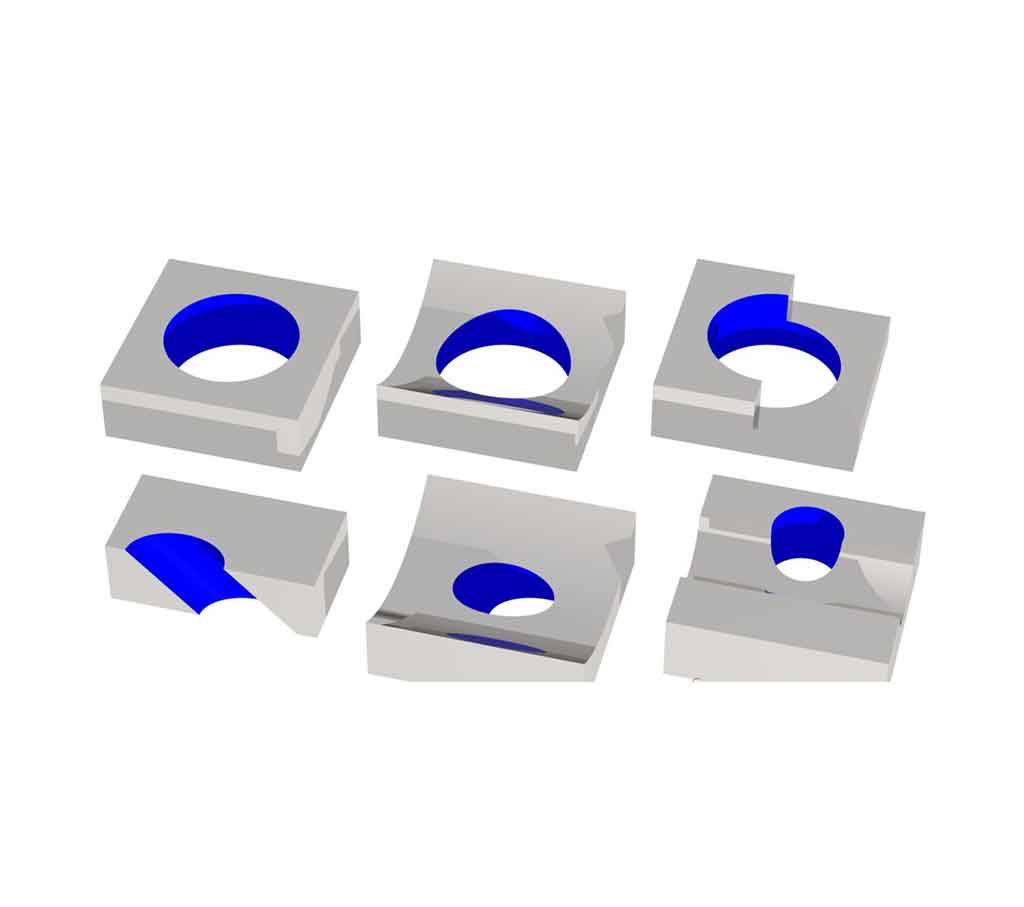

A lot of components in the industry have counter bores or spot faces on the front as well as the back surfaces of a component. Most companies use different setups to machine the two surface. Some companies make a special tool which requires interpolation and is thus inefficient. Our specialized plunge type tools allow you to create counter bores and spot face on the front and back surfaces in no time.

In metal castings, the size is generally non-uniform. But edge breaking is usually required. Our specialized tooling for deburring undefined edges is a unique technology that can be used with a robotic arm or a machining center for making uniform chamfers on all the edges despite the size variations of castings.

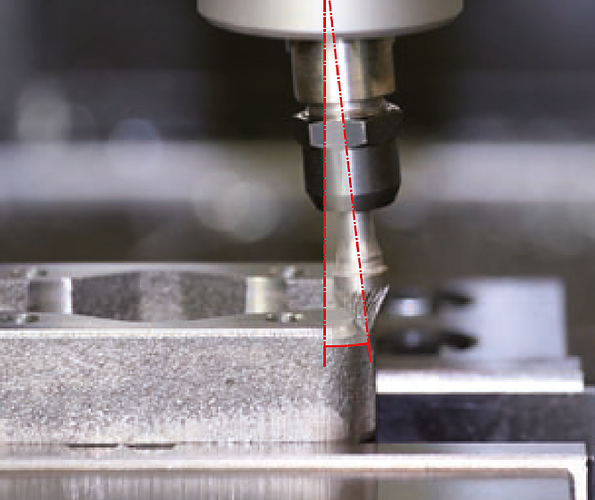

When two mating parts have a chamfer, the accuracy and finish of the chamfer becomes very important, because a few microns off, and it can become a safety hazard in heavy engineering or it may make a rattling noise in a luxury vehicle. For such challenging applications, we provide solutions with our automatic recessing tools for making accurate chamfers in the lowest possible times.

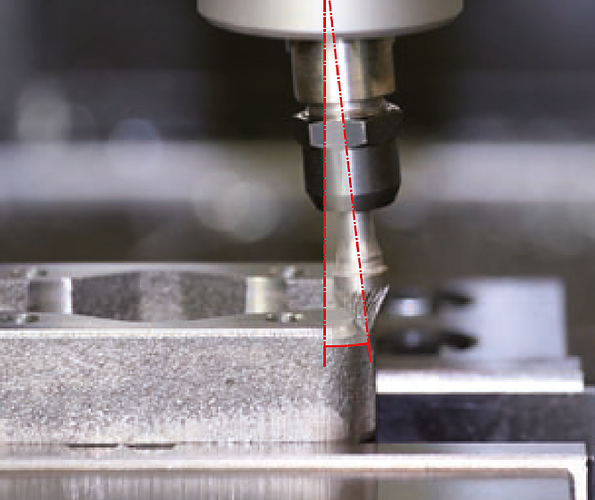

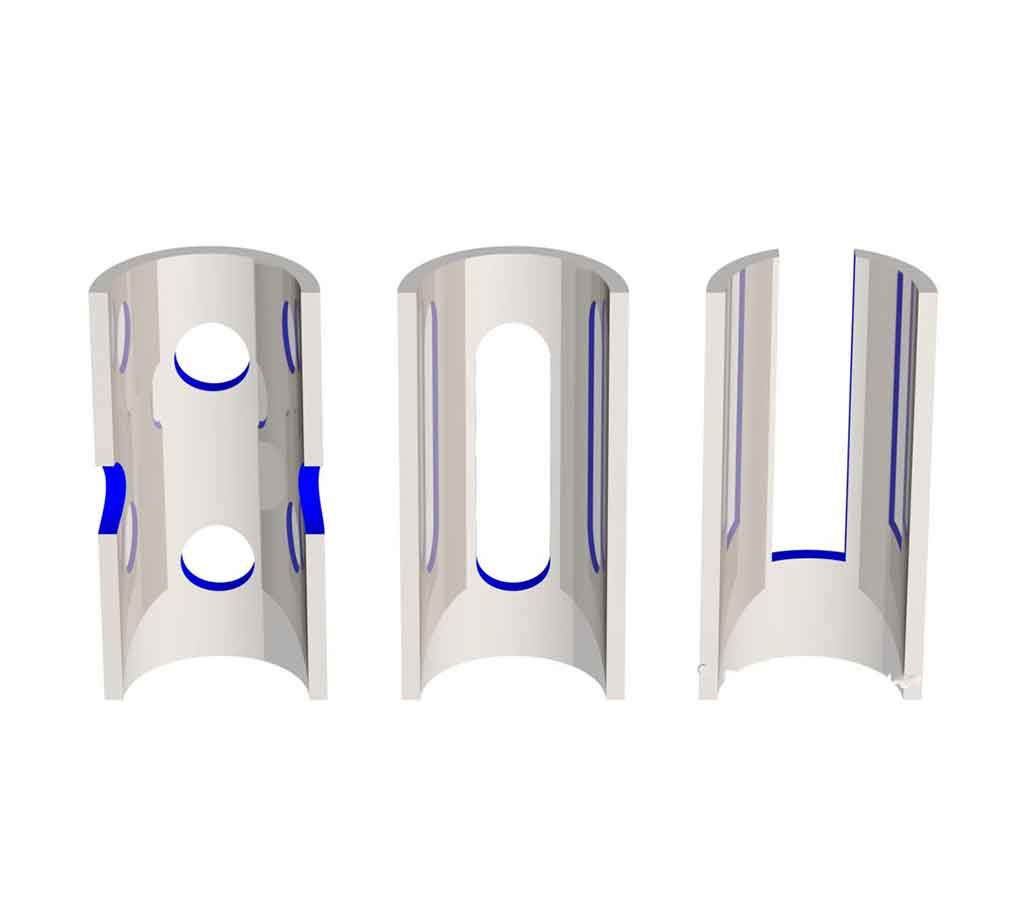

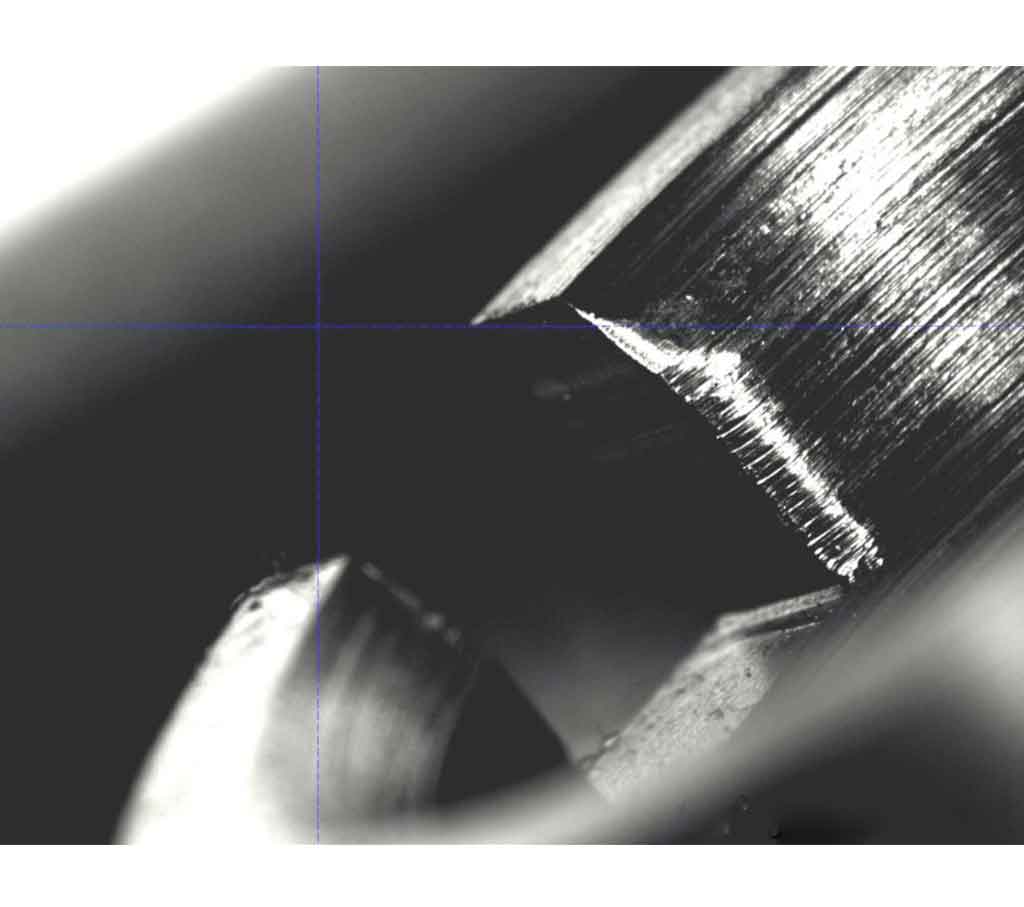

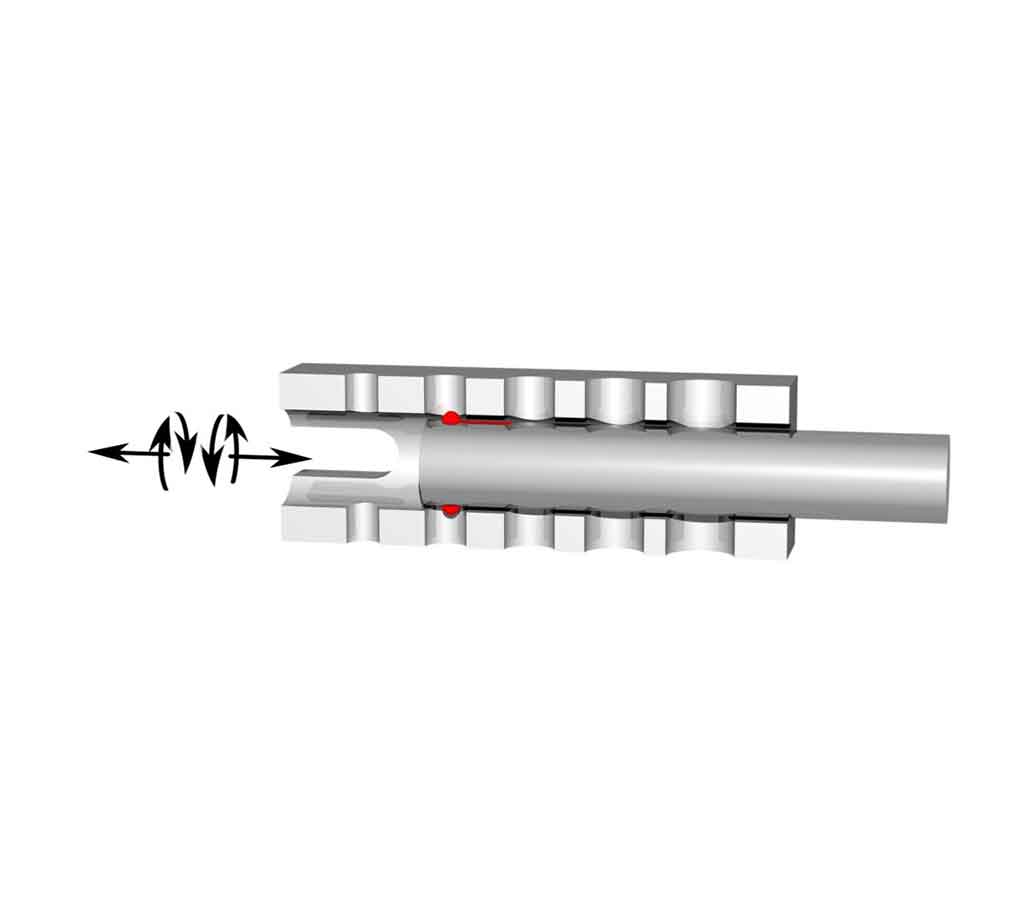

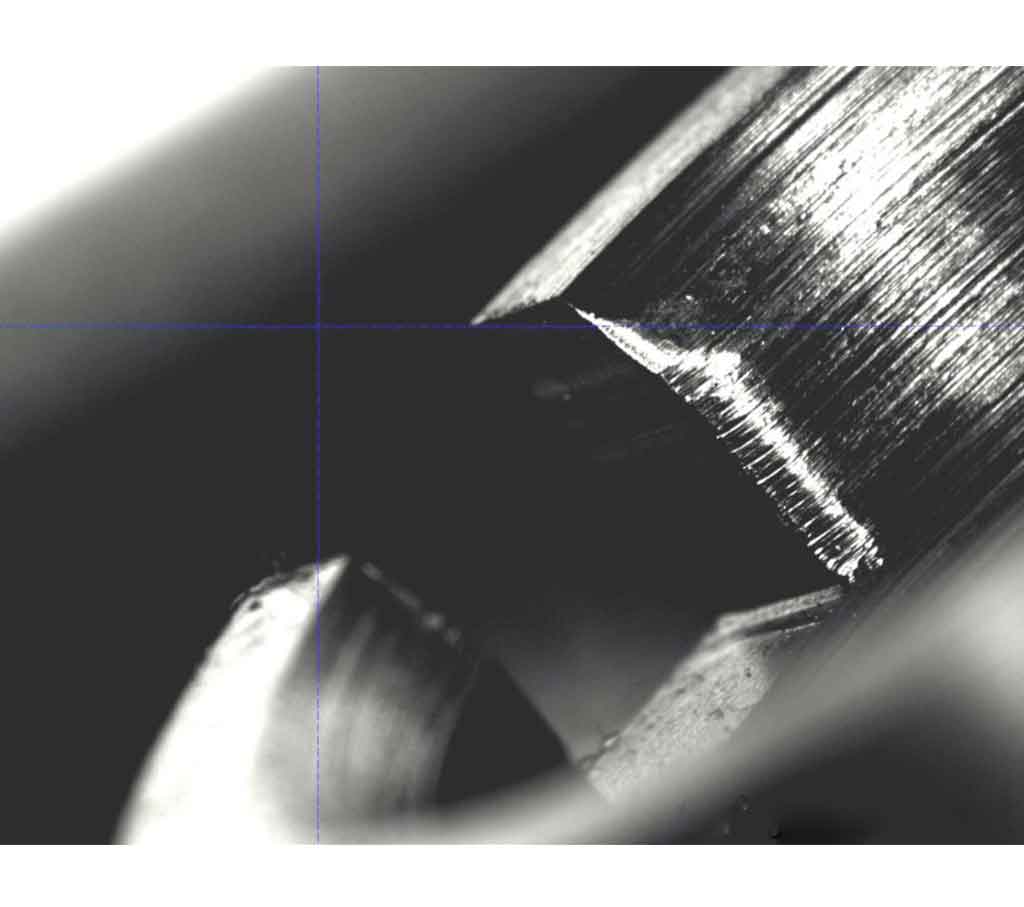

The PDT Deburrer – Mechanical high speed deburring tools for highly automated manufacturing. These tools are perfect for deburring hole-to-hole, hole-to-groove, and hole-to-slot intersections. Developed after extensive research, this tool works on a plunge cycle and does not require any interpolation or complicated programming. Multiple control mechanisms make this deburring tool the only versatile option that can operate on turning machine, machining centre, drilliing machine or any other machine on which the burr was created.

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish. Read More